So this is where the thread begins.

Here is a run down of the plan.

F22A6 engine, junk yard. Milled head with 5 angle valve job and port job.

Colt cam, stage 2. Plan for an 7500rpm red line. Maybe 8000rpm if itll carry.

PRB K20A2 Intake manifold for clearance int he ED engine bay.

B series TB, going to run OBD1

Still thinking about the exhaust manifold

DIY F2B without adapter plate.

Hasport mounts

I figured I would start a thread because today I made the first steps of progress to the build coming together. To figure out what TB I was going to use. B series or K. I had the parts, so I figured Id try it to see how it would work.

My Accord K24 TB didnt even fit the PRB IM.

Now for the B...

Turns out three of the 4 bolt holes line up. Perfect. Thats enough for me.

The PRB IM has a weird little bypass pocket. I found the perfect little thing to plug it. Its the shifter bushing kit for the acura/hondas. It has 4 o-rings and a steel sleeve, fits perfectly into the hole and plugs it right up after you punch out the freeze plug.

![Image]()

I used a bolt and nut with some crush washers to seal the hole in the middle. Some weld would work too.

Use Permatex gray very very thin layer for your gasket. Maybe slot the bolt holes out a little to completely seal the IACV port in the TB (or fill with JB weld) and to center TB a little better. Id say its at 95% right now, could be a hair better.

Anyways heres the pics. All I need to do now is drill and tap for a remove IACV plate.

Heres the plug.

![Image]()

LS TB on the PRB IM. three of four bolts right there. Throttle cable goes under the IM.

![Image]()

No overlap.

![Image]()

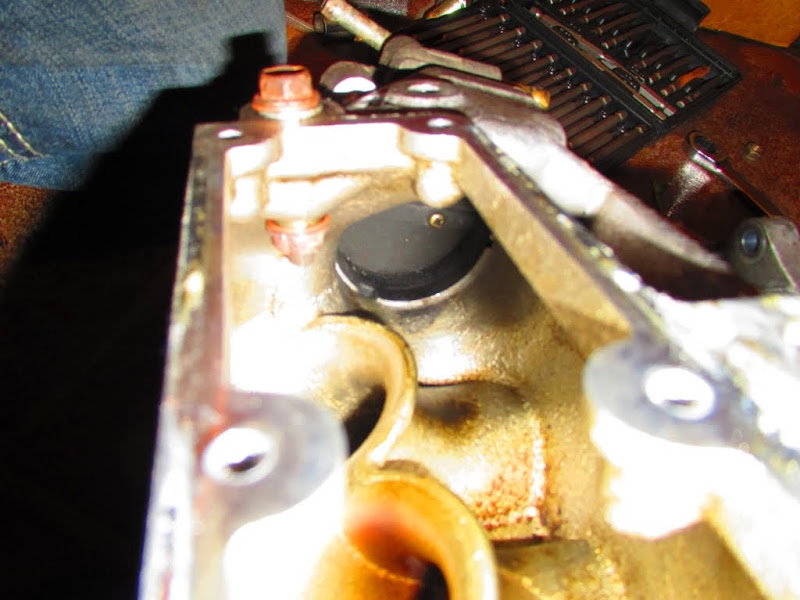

Inside view.

![Image]()

I will keep updating as I make progress.

Still need to pick up a core engine to work on, and finalize how I want to bolt this IM to the F head.

Here is a run down of the plan.

F22A6 engine, junk yard. Milled head with 5 angle valve job and port job.

Colt cam, stage 2. Plan for an 7500rpm red line. Maybe 8000rpm if itll carry.

PRB K20A2 Intake manifold for clearance int he ED engine bay.

B series TB, going to run OBD1

Still thinking about the exhaust manifold

DIY F2B without adapter plate.

Hasport mounts

I figured I would start a thread because today I made the first steps of progress to the build coming together. To figure out what TB I was going to use. B series or K. I had the parts, so I figured Id try it to see how it would work.

My Accord K24 TB didnt even fit the PRB IM.

Now for the B...

Turns out three of the 4 bolt holes line up. Perfect. Thats enough for me.

The PRB IM has a weird little bypass pocket. I found the perfect little thing to plug it. Its the shifter bushing kit for the acura/hondas. It has 4 o-rings and a steel sleeve, fits perfectly into the hole and plugs it right up after you punch out the freeze plug.

I used a bolt and nut with some crush washers to seal the hole in the middle. Some weld would work too.

Use Permatex gray very very thin layer for your gasket. Maybe slot the bolt holes out a little to completely seal the IACV port in the TB (or fill with JB weld) and to center TB a little better. Id say its at 95% right now, could be a hair better.

Anyways heres the pics. All I need to do now is drill and tap for a remove IACV plate.

Heres the plug.

LS TB on the PRB IM. three of four bolts right there. Throttle cable goes under the IM.

No overlap.

Inside view.

I will keep updating as I make progress.

Still need to pick up a core engine to work on, and finalize how I want to bolt this IM to the F head.