Motor is a stock d16z6 in eg civic

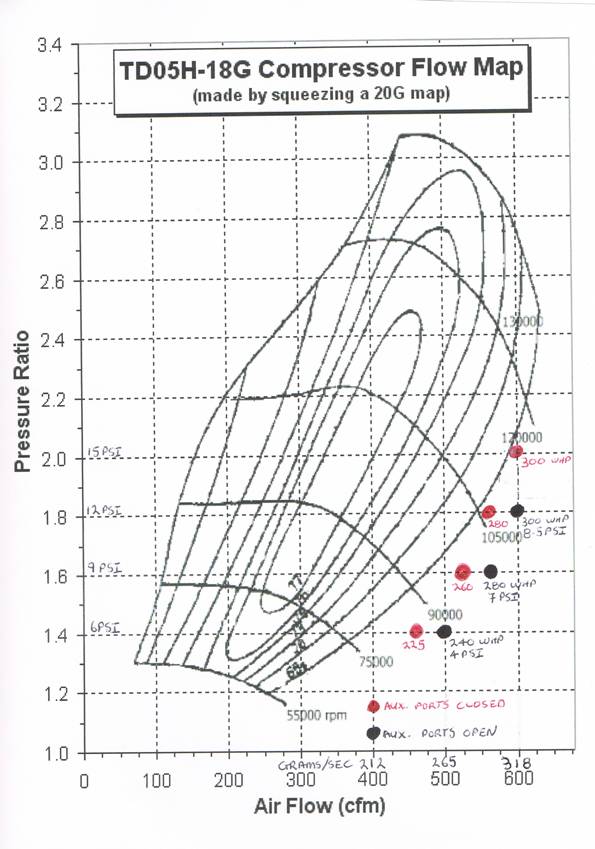

Turbo is Garrett 18g

Right now the turbosmart IWG is set to 10psi which I think is too much for my stock motor. *I'm going to order a new spring for it but I don't know what rate to order it at.

So how do I estimate how much HP the turbo will produce per psi

Turbo is Garrett 18g

Right now the turbosmart IWG is set to 10psi which I think is too much for my stock motor. *I'm going to order a new spring for it but I don't know what rate to order it at.

So how do I estimate how much HP the turbo will produce per psi