After two years of being off my old D16A6 and sitting in a box, I’m finally working on getting my JRSC originally for the D16A6 on to my DOHC ZC (Which only has recently been put back together after being apart for close to 10 years.).

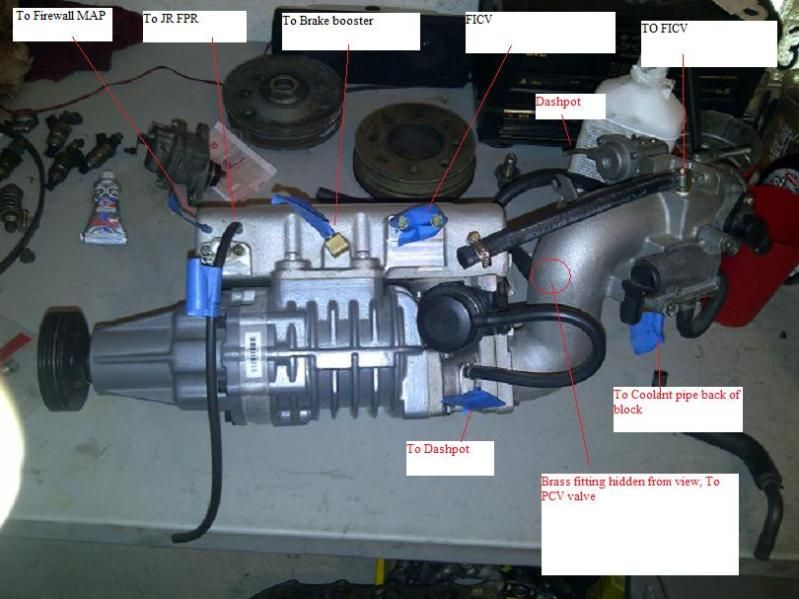

I’m a little out of my depth, everything is a learning experience for me, so after some reading and searching on the site, I believe this is how the lines need to be hooked up. I know there are a few members with D16A6/JRSC setups, if they could chime in and tell me if I have these labeled correctly or if they see any problems to let me know, that would be much appreciated.

Disclaimer: I am using the JR FPR as management for now, once the car is up and running a proper fuel management system will be sourced and sorted out.

![Image]()

I thought a picture like this might make it easier for people who need to use it in the future as well. Feel free to add some of the lines that I haven’t specifically pointed out.

I’m a little out of my depth, everything is a learning experience for me, so after some reading and searching on the site, I believe this is how the lines need to be hooked up. I know there are a few members with D16A6/JRSC setups, if they could chime in and tell me if I have these labeled correctly or if they see any problems to let me know, that would be much appreciated.

Disclaimer: I am using the JR FPR as management for now, once the car is up and running a proper fuel management system will be sourced and sorted out.

I thought a picture like this might make it easier for people who need to use it in the future as well. Feel free to add some of the lines that I haven’t specifically pointed out.